Global enterprise and hyperscale clients demand secure, certified, and verifiable data destruction – this is non-negotiable in today’s IT asset disposition (ITAD) landscape. Various methods of data destruction provide complete and irreversible sanitization, though the sustainability benefits vary with each. The most common method, shredding, physically destroys storage devices but eliminates any potential for reuse or component recovery, making it the least sustainable option. Data erasure, on the other hand, allows for secure sanitization while enabling equipment to be reused, offering the highest environmental benefit. An emerging third option, magnet recovery, provides a hybrid approach, ensuring data is destroyed while allowing rare earth elements from hard drives to be reclaimed, helping organizations meet both their security and sustainability goals.

Erase Securely, Reuse Confidently

Data erasure for storage media (HHDs and SSDs) enables secure reuse of drives. Data is erased while the drive itself remains functional. SLS’ data erasure processes are fully secure and certified to industry-leading standards, including NIST 800-88 r1, ensuring that all data is irrevocably removed before any device is repurposed. This method, which includes independent validation, delivers the same level of protection as physical destruction, but with far greater environmental and financial benefits.

When reuse is not an option, however, we continue to seek innovative techniques to minimize environmental impact without compromising data security.

A New Opportunity

While some clients require physical destruction of hard drives, they have given us the opportunity to prototype new methods for carrying out that destruction. This flexibility has allowed us to explore innovations that maintain strict data protection standards while also advancing recovery of rare earth metals.

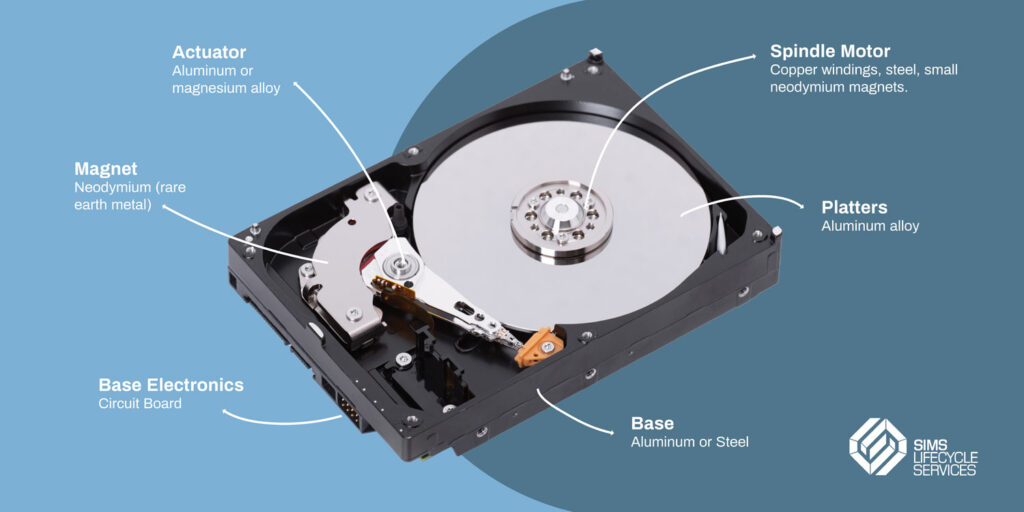

To understand the opportunity, it’s helpful to know how hard drives are constructed. Data is stored on aluminum alloy platters within the drive, while rare earth magnets—used to control the movement of read/write heads—play a critical mechanical role but are unrelated to data storage itself. These magnets are valuable and increasingly important from a materials recovery standpoint.

Harvesting magnets from end-of-life hard drives presents a significant environmental and economic opportunity. Unlike traditional recycling, which often involves shredding and smelting that can destroy valuable rare earth metals, magnet harvesting enables us to remove high-value components intact, allowing them to be efficiently processed for recovery.

We are currently collaborating with partners who bring different approaches to recovering the rare earth metals from these magnets. One partner specializes in mechanical separation, disassembling hard drives to recover individual components such as platters, magnets, aluminum, steel and circuit boards. Another partner focuses specifically on chemical recovery of the rare earth metals. They rely on SLS to isolate the magnets from the rest of the drive and deliver them as a clean, separated stream for further processing.

We are additionally exploring the use of robotics to automate our separation process, enabling higher efficiency and consistency at scale.

These initiatives demonstrate that it is possible to recover valuable materials like rare earth metals while still meeting the client’s non-negotiable requirement for certified data destruction.

At SLS, sustainability and data security are not competing priorities, they are core, complementary pillars of our mission. Our work to advance rare earth magnet recovery while maintaining uncompromising standards for certified data destruction reflects our commitment to building solutions that serve both the planet and our clients’ risk management needs.

Contact Us

Learn more about how SLS protects your data and extracts value from hard drives.