Interested in increasing your sustainability?

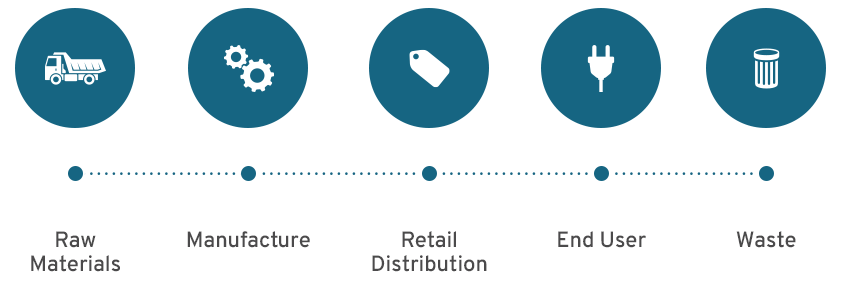

In the traditional linear economy, raw materials are extracted from the environment, manufactured into finished products, and sold to consumers. At the end of their useful lifecycle, products are disposed as waste, either in a landfill or at an incineration site. The result of this “take, make and waste” approach of the traditional linear economy, unfortunately, is that all materials with reuse potential are permanently lost.

The linear economy is characterized by high resource consumption, a high carbon footprint, high waste production, and environmental degradation. The focus is on producing and consuming new products, regardless of the long-term consequences.

The resulting waste of this practice includes an escalating amount of electronic and IT equipment such as computers, printers, laptops and phones, as well as an ever-increasing amount of internet connected devices such as watches, appliances and security cameras. More electronic devices are in use than ever, and new generations of equipment rapidly follow one another, making relatively new equipment quickly obsolete. Each year, approximately 50 million tons of electronic and electrical waste (e-waste) are produced, but less than 20% is formally recycled. The remainder, over 40 million tons annually, is incinerated, dumped or ends up in a non-regulated informal circuit, with all associated health, safety and environmental hazards. “E-waste is now the fastest-growing waste stream in the world,” according to a joint report by the World Economic Forum, World Business Council for Sustainable Development, United Nations Environment Programme, International Telecommunication Union, International Labour Organization and other E-waste Coalition members. “If nothing is done,” notes the report, “the amount of waste will more than double by 2050, to 120 million tons annually.”

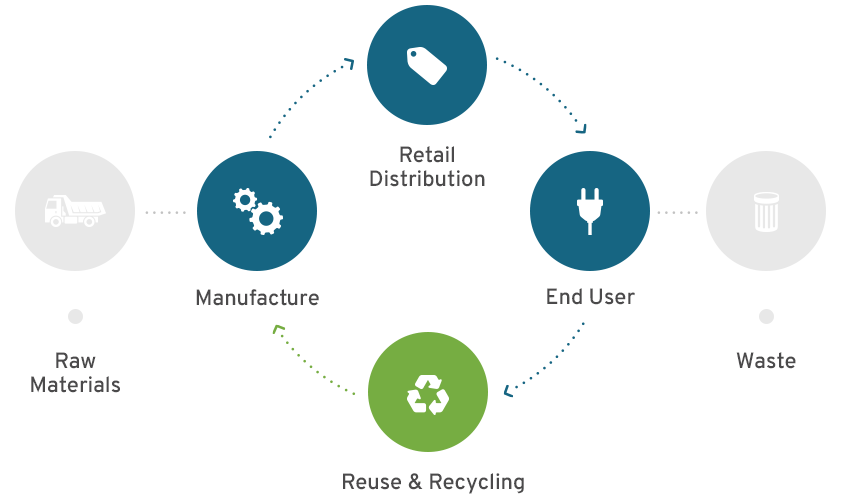

Fortunately, there has been a global transition towards a circular economy. The focus of the circular economy is to create a regenerative and sustainable system that minimizes waste, optimizes resource reuse, and promotes long-term environmental and economic health.

Attention is paid to extending the useful life of products, restoration of used products, use of renewable energy, and elimination of toxic chemicals and waste. Circular models avoid depletion of finite raw material resources, of which electronic devices use a significant share.

If the whole product cannot be reused, components can be harvested for use for repair or spare parts, and materials such as steel, aluminum, copper, precious metals and some plastics are recovered and used as feedstock for next generation products.

This approach is especially relevant to electronics and IT equipment. When a new device or technology standard is introduced, or when a business scales up or down, refocuses or refreshes its activities, large volumes of IT products are replaced or become obsolete for use in their current environment.

Corporate and data center hardware refresh cycles typically occur every three to four years, primarily due to the evolution of technology. Standard refresh cycles allow for upgrades of assets on a predictable and budgeted schedule. Companies that do not refresh their technology on a scheduled basis react in an ad-hoc manner when outside factors, such as antiquated and unsupported software, hardware failures, the expiration of warranties or leases or overall investment depreciation force a hardware update.

Regardless of the motivation for the refresh, there are opportunities to extend the lives of retired IT equipment, reuse parts and recover raw materials. This is at the heart of the circular economy: extending the product lifecycle and recovering product resources while minimizing the environmental impact from mining, production and transportation.

This white paper focuses on currently available lifecycle circularity potential of electronic devices and aims to retain the greatest possible value of products, parts and materials. The circular approach can be addressed throughout the entire lifecycle of an IT asset, including the design, usage and end of first life disposition.

Products in a circular economy are designed and created with prolonged multiple lifecycles in mind and are to be reused as often as possible before ultimately being recycled. Longevity, sustainable materials, robust construction, modular design, ease of reuse and repairability are designed into the products. This is essentially the opposite of planned obsolescence in which products are designed for a limited lifespan.

How a product is manufactured will greatly impact longevity and the ability to cost-effectively repair the product. Thoughtful design by electronic OEMs, such as using clips instead of glue to secure components in place, reducing the number of screws used and enabling efficient disassembly allows for parts repair, replacement and targeted reuse.

In recent years, a number of “right to repair” laws have been enacted. These laws ensure the ecosystem of reuse and repair is supported through the availability of spare parts, tools and repair manuals.

While limiting repairability has received criticism from end users and repair advocates, many manufacturers state that their opposition to such legislation is based on the need to ensure that repairs are made correctly and conform to safety and regulatory compliance. Unauthorized repairs may also expose customers to risks and personal harm from undertaking repairs they are not sufficiently skilled in or when not following the manufacturer’s instructions and guidelines.

OEMs additionally understand that redesigning products and business models can be cost prohibitive and potentially exposes their intellectual property and processes to competitors.

The inability to repair or upgrade electronic devices, coupled with reluctance to pay exorbitant repair costs, has led to a significant amount of usable electronic products being discarded after their first life.

The use of a product, rather than owning it, is the ultimate circular business model. Leasing and subscriptions are examples of using a product as a service, where the responsibility for maintenance, repair, and end-of-life management rests with the service provider, encouraging product durability and efficient and extended use of the product.

Purchasing vast amounts of corporate computer equipment requires responsible and educated procurement practices. Research and evaluation of brand quality, design, performance, warranty and support is vital to not only the daily performance and reliability of the equipment but to the value retention of the investment and total cost of ownership (TCO).

Durable electronic devices with the ability to be repaired and upgraded not only extend the life of essential company assets but provide the sustainable benefits that are realized with utilizing a product throughout its productive lifecycle.

Careful and proper usage allows electronic devices to function at a high level for extended periods of time. Combined with proper care and maintenance, using an electronic device as directed provides the opportunity for multiple extended lifecycles and demonstrates circular practice.

Extending device lifecycles provides obvious financial benefits by prolonging refresh cycles and delaying the purchase of new equipment. The environmental benefits to be realized, however, can also be significant.

Upgrading existing devices offers a variety of advantages, including greater performance, access to new features, increased security, longer battery life, enhanced graphics, additional storage and enhanced connectivity. This delays the need for replacement and maximizes the value of the initial investment.

Extended warranties prolong the life of aging devices through additional repair and maintenance, reducing long-term wear and tear. Warranties encourage companies to repair rather than replace, maximizing the product lifespan and thereby reducing e-waste; all pillars of the circular economy.

Devices which have been upgraded and/or properly maintained under warranty have far greater resale potential at the end of the warranty period and the product’s first life. IT Asset Disposition (ITAD) vendors refurbish and remarket redundant electronic devices, further extending the product lifecycle, while providing financial return on the initial investment, and, in turn, lowering the total cost of ownership.

Preparation for Second Use

Most enterprise companies use a vetted ITAD vendor to reuse or recycle IT assets that are no longer fit for their initial use. IT assets require minimal preparation prior to sending to an ITAD vendor. It is essential, however, that all units are unencrypted and unlocked so that the data within them can be accessed and destroyed. Devices which are left encrypted cannot be made data-safe and the ITAD vendor has no option other than to destroy and recycle the locked device, eliminating the environmental and financial benefits that accompany a redeployed asset.

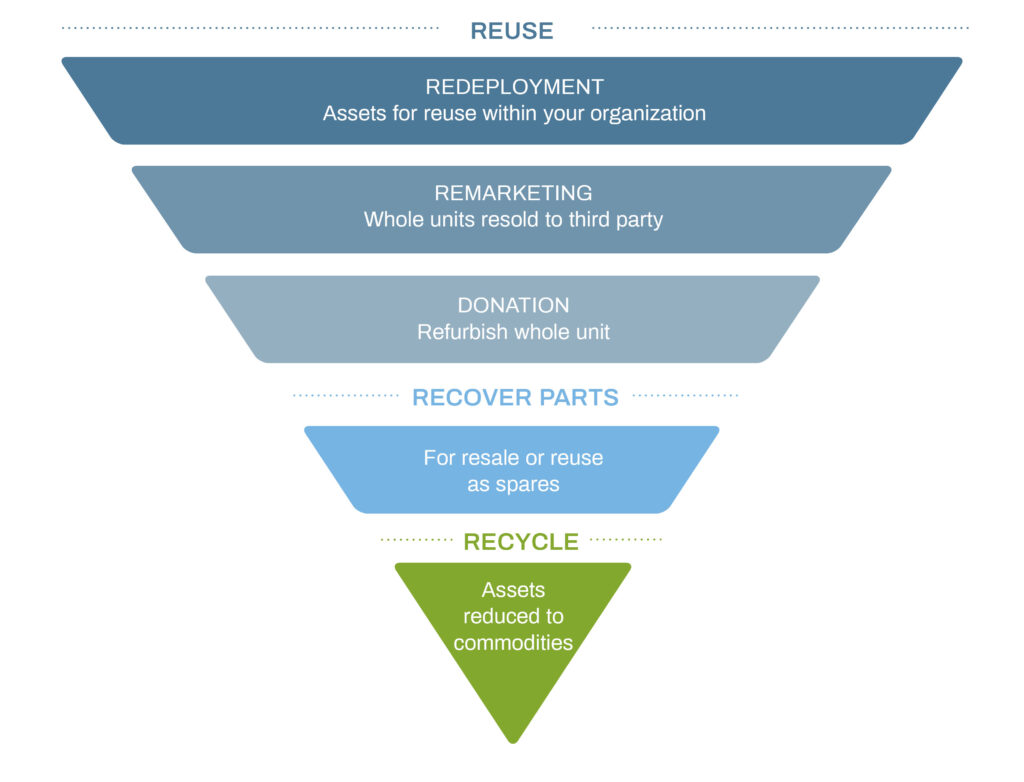

An ITAD vendor has five options for extending the lifecycle of IT assets: redeployment, remarketing and donation provide a second life for whole units, while recovery of parts and recycling present second life opportunities for components and raw materials. Each step has its own specific characteristics and contributes to the value chain in its own way.

If IT products can’t be reused within their existing organization, they can be matched to an external party’s requirements and resold or donated. In preparation for reuse, products are data wiped, cleaned, refurbished and repaired or modified if necessary. Worn or defective parts may be replaced. An operating system is typically installed and the equipment is sold on the open market or donated to a preferred charity.

Reuse of whole units is by far the most sustainable practice for electronic devices. While parts recovery and recycling play an important role in managing waste and recovering valuable materials, reuse offers distinct environmental and economic benefits by reducing energy consumption, waste generation, resource depletion, pollution, and emissions. In fact, according to “Data Sanitization for the Circular Economy,” a 2022 collaborative IT industry white paper, secondary use of IT assets has proven to avoid up to 275 times more carbon emissions than the best recycling process.

Did you know? The SLS Sustainability Calculator is one of the few calculators on the market that calculates embodied carbon avoided through reuse of whole units and parts, in addition to recycling of IT assets.

It is important that all the options and services described below are carried out in accordance with the strictest security, safety and environmental certification in order to ensure compliance with local legislation and regulations.

Redeployment

Redeployment of previously retired products in your own organization is the most cost-effective and circular method of reusing IT equipment. Assets which are (temporarily) no longer serving their intended purpose are collected, data-wiped, cleaned and tested so they can be redeployed to a more suitable capacity within your company.

Redeployment of IT assets is considerably less resource intensive compared to buying new assets as it eliminates the need to extract finite virgin resources and avoids the carbon emissions that are associated with the production of a new device, including mining, transportation and processing. By way of illustration, manufacturing accounts for almost all of a smartphone’s carbon footprint in its first year of use, with 95% of carbon emissions coming from manufacturing processes.

In addition to reducing your company’s carbon footprint, circular practices contribute to corporate environmental and Scope 3 reporting requirements.

A Reminder: Time is the enemy of electronics. Storing and stockpiling unused electronics keeps e-waste out of landfills but eliminates the potential for these devices to be reused, necessitating the production of new equipment and its associated environmental impact.

Remarketing and Donation

If IT products can’t be reused within their existing organization, they can be matched to an external party’s requirements and resold or donated. In preparation for reuse, products are data wiped, cleaned, refurbished and repaired or modified if necessary. Worn or defective parts may be replaced. An operating system is typically installed and the equipment is sold on the open market or donated to a preferred charity.

As noted, enterprise computers, laptops, phones and servers are generally replaced every three to four years but can be reused in their entirety by another user in a new environment.

Remarketing maximizes a company’s return on investment and can help to offset the cost of the new technology. ITAD programs have the potential be financially positive and qualified vendors have vast experience reselling redundant equipment with substantial value return.

Fully refurbishing and reusing IT equipment additionally allows the environmental benefits detailed in the Redeployment section above to be realized.

If a product is not reusable in its entirety, parts and components can be recovered for resale or for use as spare parts internally, giving them a second or even third lifecycle. Common parts harvesting programs recover laptop and server component parts including memory, processors, circuit boards, hard drives and optical drives, as well as metal brackets and housings, cards and power supplies. Data bearing equipment is erased and the recovered components are tested and provided a second lifecycle after being sent back into the distribution stage. Certified software overwrites original data on storage media making confidential data irretrievable.

In the circular economy, recycling offers the smallest opportunity for resource recovery and decarbonizing the supply chain.

If a product and its parts are no longer reusable, recycling does enable the recovery of component materials, which can be used in manufacturing next generation products. Component materials commonly recovered from e-waste recycling include steel, aluminum, copper, precious metals and plastic. These materials are placed back in the raw materials production chain and reworked into new feedstock that manufacturers can use to produce new products – a form of urban mining. Returning recycled metals to the ore stream to create new metals is a far more energy efficient process than using virgin mined ores and limits the mining and preparing of new ore. Recycling aluminum, for example, results in 90% lower CO2 emissions compared to creating aluminum from ores.

An interesting fact concerning plastics: these can be returned to an OEM plastics compounder who can, in return, deliver separated granulates back to the electronics manufacturer for reuse in new products and in this way a closed loop is created.

Advanced recycling techniques and expertise mean a high percentage of materials can be recovered with minimal environmental impact.

In addition to reducing the overall carbon impact, resource conservation and financials gains, the circular economy practice provides a multitude of additional benefits, both environmental and social:

Reuse and recycling are vital to the circular economy. As more electronic devices are manufactured every year, the amount of e-waste will naturally continue to increase.

Annual generation of electronic waste is rising five times faster than documented e-waste recycling, per the UN’s fourth Global E-waste Monitor. As production of new devices continues to increase, however, the report notes that recycling rates are actually expected to drop, simply unable to keep up with increasing amounts of waste every year.

Positive steps are being taken across the distribution channel, however, as both manufacturers and consumers are adopting more sustainable practices. Manufacturers must continue transitioning to more circular business models which include product repairability and a more sustainable product design for a longer lifespan. In addition to requiring this sustainable design, businesses and end users can extend the life of IT assets through proper usage, extended warranties, maintenance, refurbishment and redeployment.

Systems, products and components continue to offer value, either through complete or partial reuse, or as a source of raw materials when recycled. Furthermore, this approach minimizes the carbon impact of products, reduces depletion of raw materials and decreases landfill volumes. The extended use of virgin raw materials also poses potential threats in the form of supply chain disruptions.

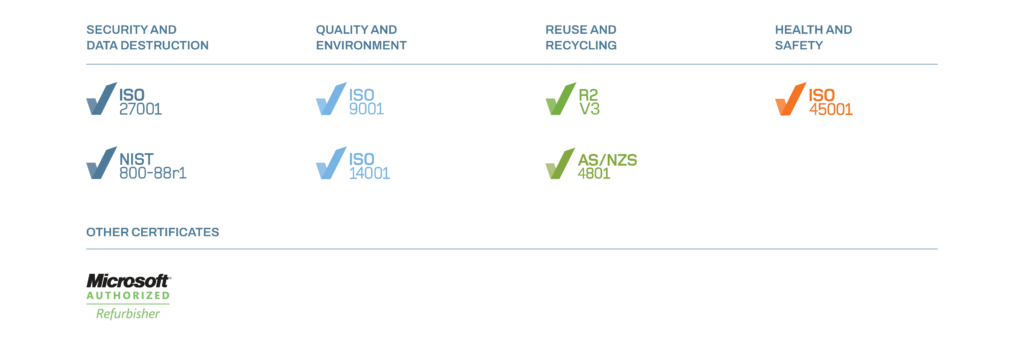

It is essential to select an ITAD vendor who possesses the experience, expertise, track record and specialization in serving organizations similar to yours and complies with all relevant legislation. Factors to take into account include the vendor’s years of operation, client references, industry certifications (ISO 9001 ISO 27001, R2, etc.) and verified documentation of all data destruction, remarketing and recycling. World class electronics processors return financial value to their clients through the resale of units and components while incorporating the carbon avoided via the resale into Scope 3 reporting.

Most large organizations today issue a detailed RFP to evaluate ITAD vendor capabilities and strengths. RFP data generally includes information regarding compliance, data security, sustainability and value recovery. Prioritizing corporate objectives and goals into the RFP will ensure that your organization identifies a vendor that meets these specific requirements and objectives.

Sims Lifecycle Services (SLS) is a pivotal division of Sims Limited, a global leader in the circular economy. We provide solutions to enterprises and hyperscale data centers by retiring IT assets to maximize value, destroy data and responsibly manage IT equipment. Global clients value our ability to securely process a wide range of asset types, provide holistic geographic coverage and offer IT asset remarketing, redeployment and recycling services. Providing services to clients in over 100 countries, SLS possesses the global reach to support worldwide IT Asset Disposition (ITAD) programs as a single-source provider. SLS supports the overall Sims mission to create a world without waste to preserve our planet while continuously innovating to remain at the forefront of the ITAD industry.

Clients working with SLS can entrust all aspects of the process to a single party. We have extensive knowledge of hazardous waste, materials, collection, secure transport, dismantling, sorting and recycling as well as redeployment of IT equipment. Our processes are defined, predictable and repeatable, eliminating the gaps that inherently exist with a multi-vendor solution.

SLS’ award-winning Sustainability Calculator provides our clients with the most complete environmental reporting in the industry for both reused and recycled electronic materials. Combining the most up to date industry information with our own proprietary data, the calculator produces industry-leading environmental reporting that contributes to Scope 3 reporting. Internal data, including assay reports, regional transport and the renewable energy utilized in our Circular Centers, ensures the calculator accurately quantifies all processing information. Our internal assays allow us to include plastics and glass recycling reporting, which can be missed in other calculators.

We are active members of multiple global organizations focused on the sustainable management of the lifecycle of IT assets, including our continued partnership with the Open Compute Project (OCP) which provides cost savings and sustainability to data centers through the refurbishment and redeployment of redundant equipment. This enables organizations to acquire high-performance servers and components at a fraction of the cost, contributing to substantial cost savings, resource conservation, carbon avoidance and extended product lifecycles.

SLS offers a complete, integrated range of services, for reuse of systems, products and components, as well as materials recovery and recycling. We also ensure obsolete products and e-waste are disposed of in a proper, safe, secure and environmentally sound manner. We help you to securely and sustainably reuse electronics as part of your sustainability program.

Interested in increasing your sustainability?