Demonstrating how a recycling partnership can deliver value and result in sustainable material reuse and remanufacturing.

Making Sustainability Profitable

Making Sustainability Profitable

Demonstrating how a recycling partnership can deliver value and result in sustainable material reuse and remanufacturing.

Hewlett-Packard (HP) is a multi-national information technology company, which markets printers, PCs, mobile devices and services to businesses and consumers across the world. Its mission is to make life better for everyone, everywhere.

HP recognizes the circular economy is driving a new approach to how we produce and consume products and services, and embraces this idea to create value for their business, customers and society.

Both HP and Sims Lifecycle Services (SLS) have long track records of reducing environmental impacts, and enabling a partnership approach to collaboration on resource recovery and reuse.

HP is reinventing the way it designs, manufactures, uses and recovers its products as it actively moves toward a resource-efficient economy.

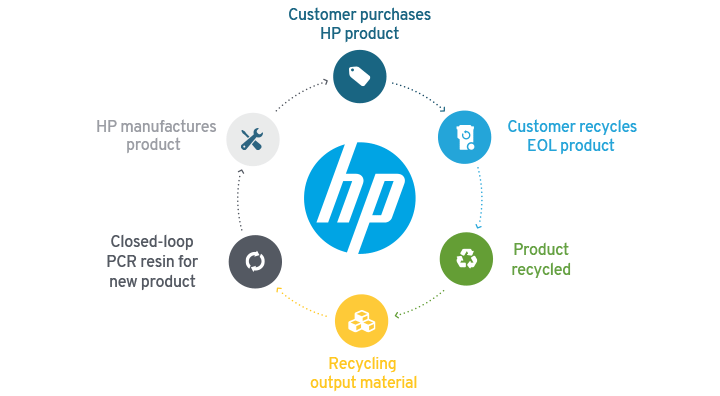

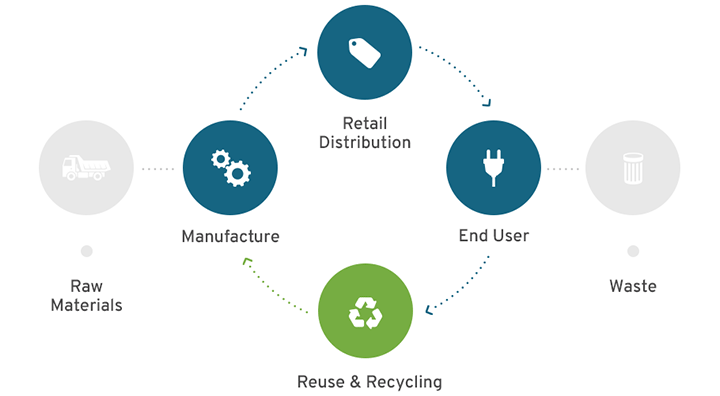

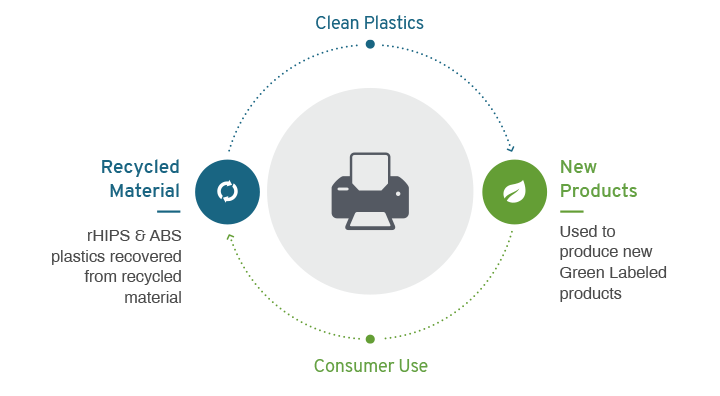

A key concept of the circular economy is the materials cycle – moving from an unsustainable linear model to a circular model. To achieve a healthy materials cycle (see diagram), and reduce its product-related environmental impact, HP wanted to work with SLS to create a sustainable plastics recovery strategy.

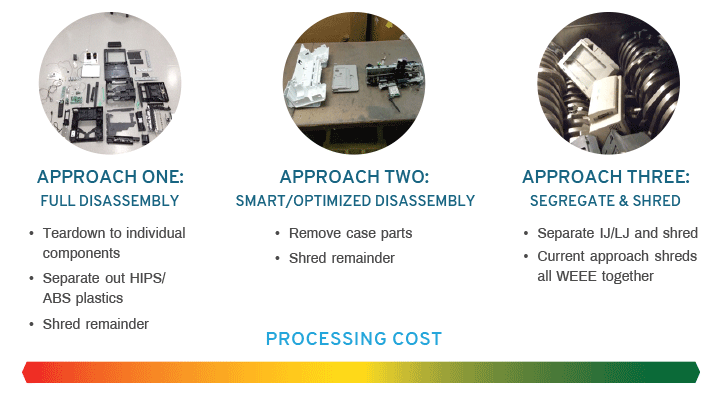

HP and SLS embarked on years of collaboration and discussion. There was a significant experimentation period – trialing many approaches to materials recovery, analyzing impacts and costs, reviewing approaches and refining until we reached a solution.

The most economically-viable solution was to collate material from HP returns and other sources, and process via mechanical shredding and separation.

SLS was able to recover rHIPS and ABS plastics in two HP-specific colors-ramping up from 40 metric tonnes of material to 320 metric tonnes-in just four months after the process was implemented.

These high-quality, closed-loop plastics are being used to manufacture new products, which will have a Green Label to identify them as being manufactured with post-consumer, closed-loop recycled content.

The result is an industry-leading solution in circular design and practice, with HP taking responsibility for its products throughout the entire lifecycle.